Call us now

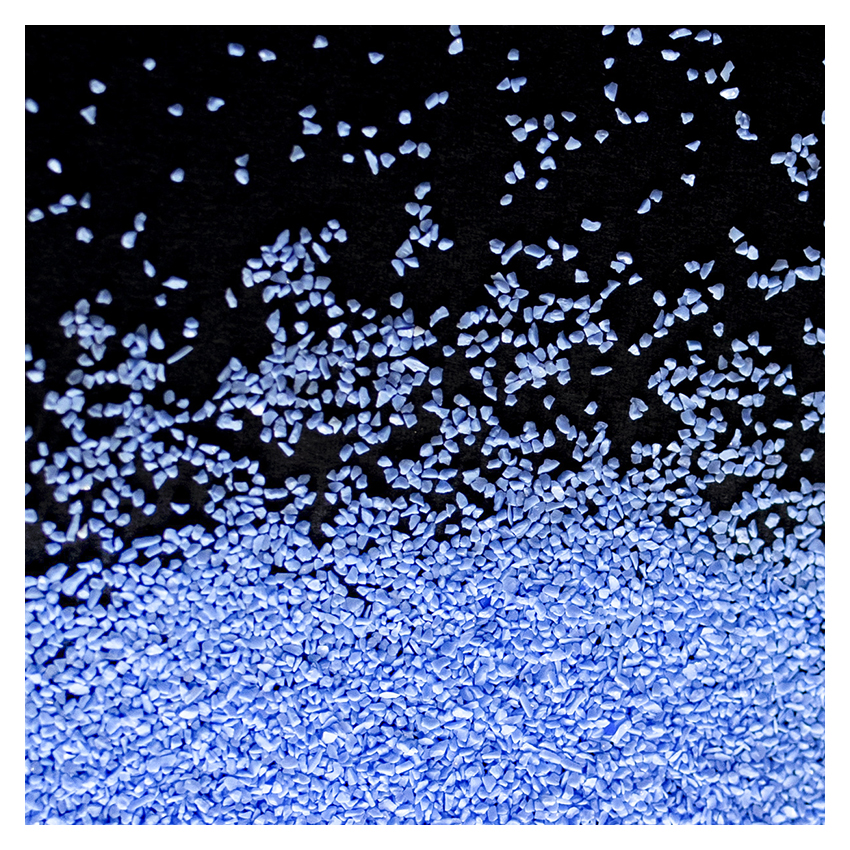

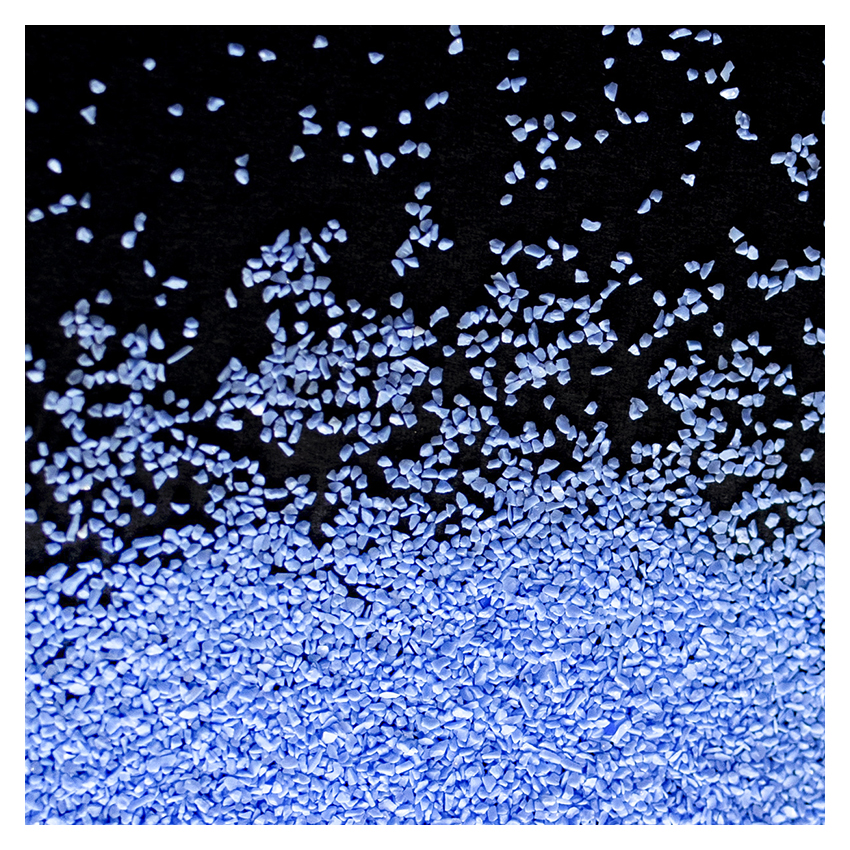

Blue Ceramic Corundum Grit

180.0 INR/Kilograms

Product Details:

- Product Type artificial abrasive

- Chemical Composition Al2O3 : 99.22% Na2O: 0.08%

- Grain Type grit

- Color bue

- Usage granite polishing

- Shape angular

- Material aluminium oxide

- Click to View more

X

Blue Ceramic Corundum Grit Price And Quantity

- 25 Kilograms

- 180.0 INR/Kilograms

Blue Ceramic Corundum Grit Product Specifications

- aluminium oxide

- grit

- angular

- 0.15 m

- granite polishing

- bue

- artificial abrasive

- Al2O3 : 99.22% Na2O: 0.08%

Blue Ceramic Corundum Grit Trade Information

- Shanghai

- Paypal Cash Advance (CA) Cash in Advance (CID) Telegraphic Transfer (T/T) Western Union Letter of Credit (L/C)

- 300000 Kilograms Per Month

- 2 Week

- Free samples are available

- 25 kg per sack/ drum, 1 ton per bag/ pallet

- Africa Asia Australia Central America Eastern Europe Western Europe Middle East North America South America

- All India

- ISO9001: 2015, ISO14001

Product Description

Ceramic alumina abrasives are produced using the sol-gel method.Here are the key points:

1. Characteristics of Sol-Gel Ceramic Alumina

Microstructure:

The grains are extremely fine (100-500 nm), much smaller than traditional alumina abrasives.

Self-sharpening:

During grinding, the tiny grains continuously expose new sharp edges, maintaining cutting efficiency and extending tool life. Toughness:

The grains exhibit higher toughness (about double) compared to traditional fused alumina, reducing wear and improving durability.

Applications:

Ideal for grinding tough materials like tool steel, stainless steel, and heat-resistant alloys.

2. Features of Grinding Tools Made from Ceramic Alumina

High Cutting Efficiency:

Sharp grains enable deep cuts and high feed rates, doubling metal removal rates.

Shape Retention:

High toughness keeps the grinding wheel shape stable, ideal for precision and profile grinding.

Long Lifespan:

Lasts 5-10 times longer than traditional wheels, reducing replacement frequency.

Self-sharpening and Non-Clogging:

Maintains consistent performance with minimal dressing needed. Cost-Effective:

Superior to traditional wheels, cheaper than CBN or diamond, and compatible with standard equipment and fluids.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Abrasive Media' category

Send Inquiry

Send Inquiry