Call us now

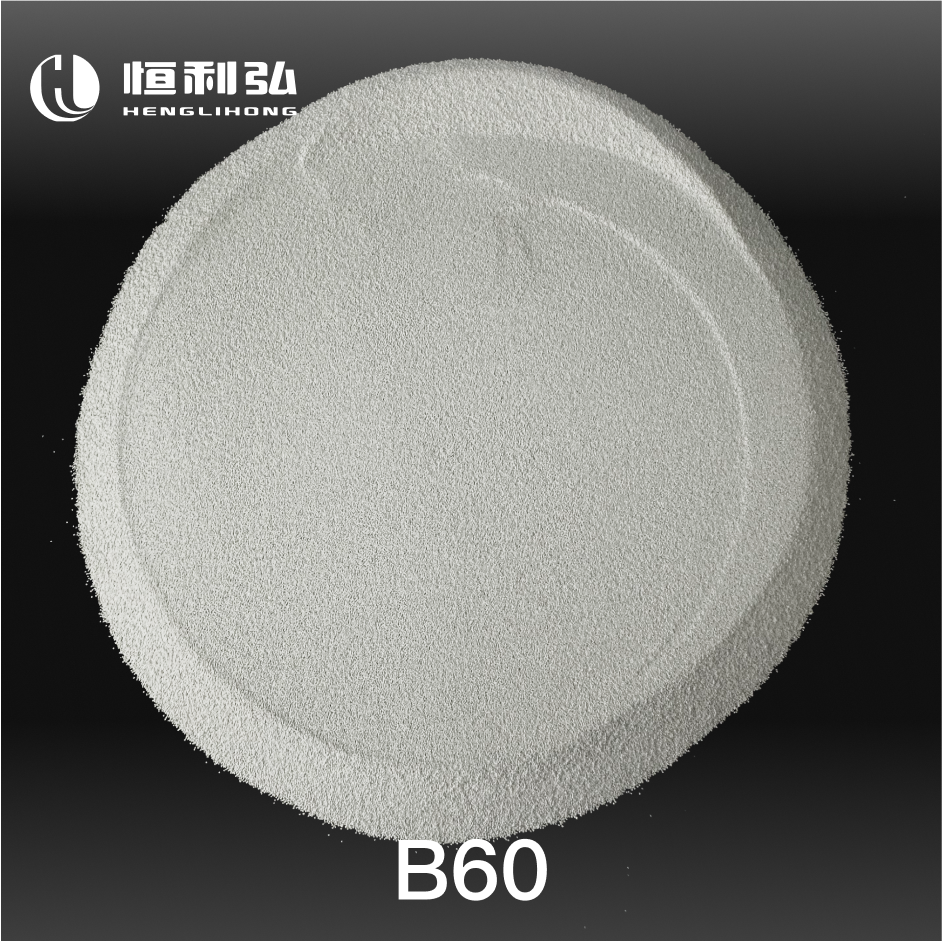

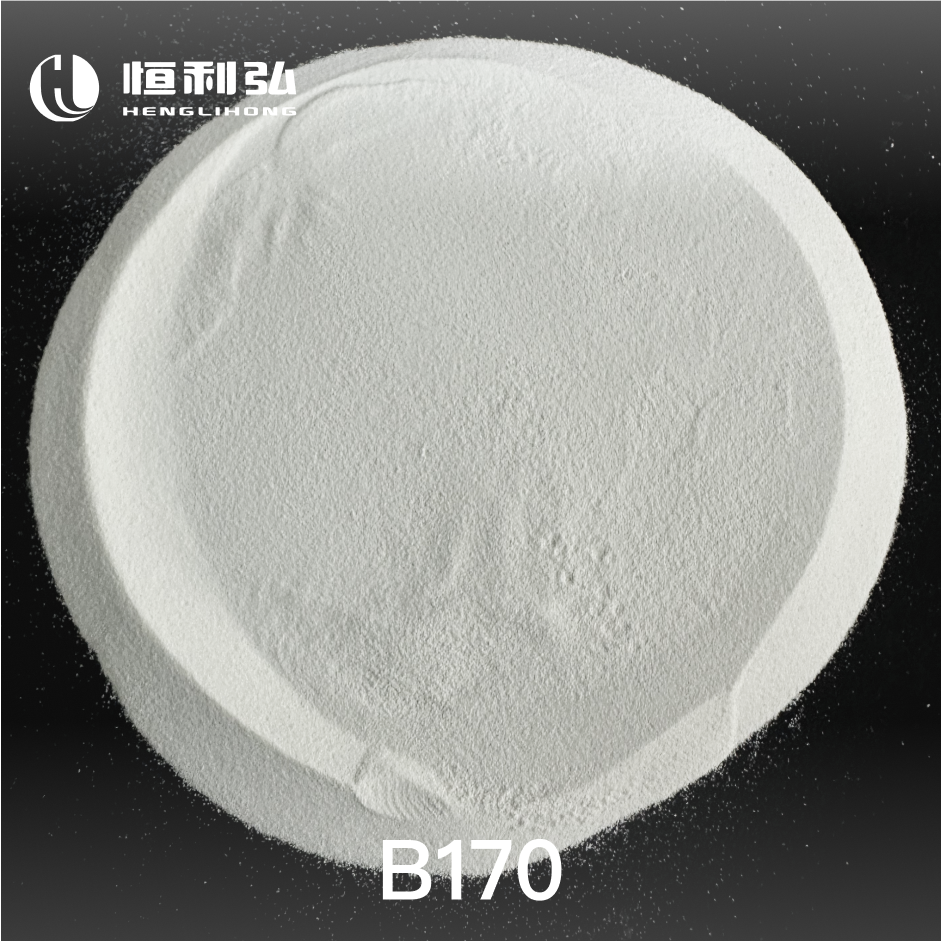

Ceramic Shots

Product Details:

- Product Type artificial abrasives

- Usage Industrial

- Size Standard

- Color White

- Ceramic Type Other

- Material Alumina Ceramic

- Warranty 12 Months

- Click to View more

Ceramic Shots Price And Quantity

- 25 Kilograms

- 1000.0 INR/Kilograms

Ceramic Shots Product Specifications

- Industrial

- artificial abrasives

- White

- 12 Months

- Standard

- Alumina Ceramic

- Other

Ceramic Shots Trade Information

- shanghai

- 300000 Kilograms Per Month

- 10 Days

- Yes

- Free samples are available

- 25 kg per bag/ drum, 1 ton per bag/ pallet

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO9001: 2015, ISO14001

Product Description

Features

High rebound rate, can evenly cover complex geometric shapes.

High hardness and toughness, with higher energy impact transmission effect.

Provide a smooth and uniform surface finish to avoid contamination.

Extremely long service life, ensuring overall operation efficiency and cost.

Certified with ISO9001:2015 and ISO14001 standards.

Very low levels of particle embedment.

No need for decontamination post-treatments for non-ferrous alloys.

Replaces glass beads, steel shots.

Suitable for pneumatic sandblasting machine, wheel blasting machine.

Suitable for shot blasting and shot peening processes.

Applications

Used for shot peening of aircraft horizontal and vertical tail fins.

Strengthening fuselage skin structural partsIncreasing the surface hardness and residual compressive stress of aircraft landing gearUsed for secondary shot peening to reduce the surface roughness of landing gear.

Inhibit the expansion of micro-cracks and pitting corrosion on the surface of high-temperature and high-load single crystal blades.

Extending the service life of dental implants and cardiovascular stents.

Improving the surface defects of surgical instruments.

Used for surface treatment of stainless steel products in the food industry.

Improve surface finish of household appliances and buildings.

Improve surface strength of automobile engine parts, gears, and suspension systems.

Cleaning of welded steel parts, castings, and forgings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ceramic Media' category

Send Inquiry

Send Inquiry