Call us now

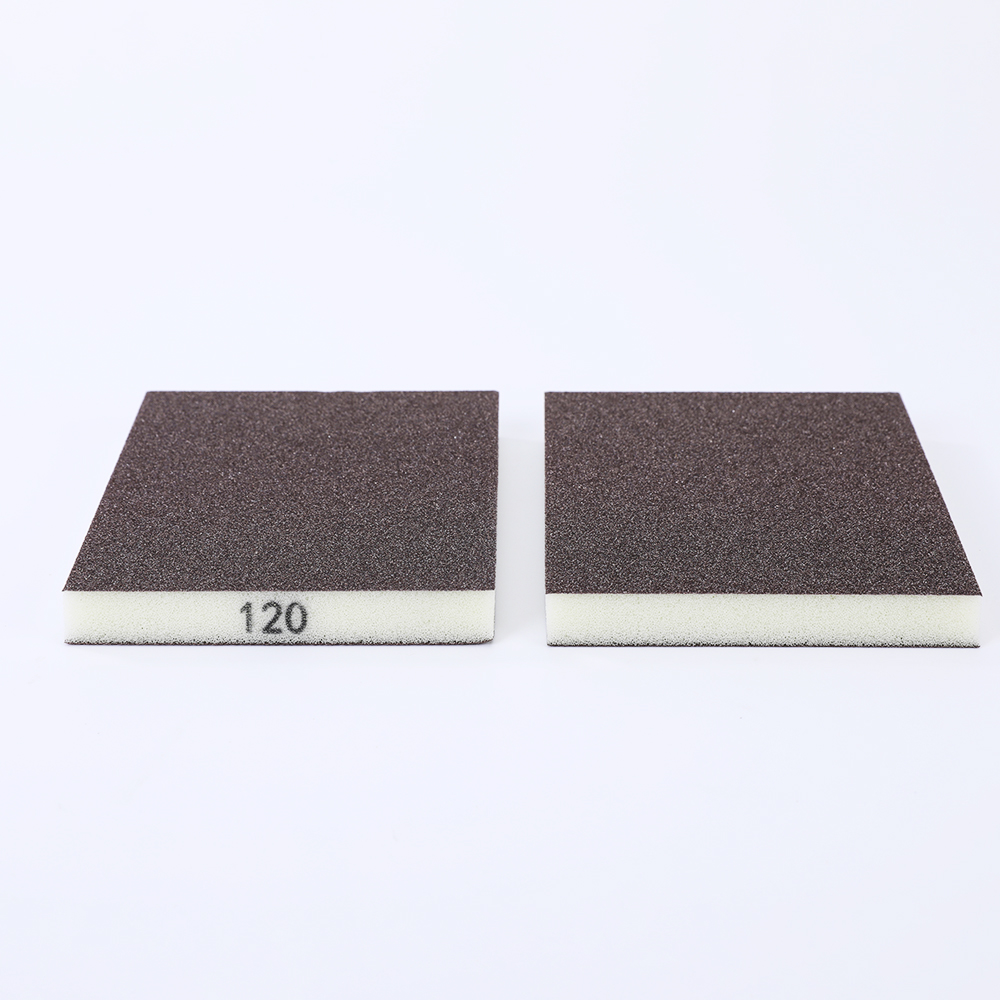

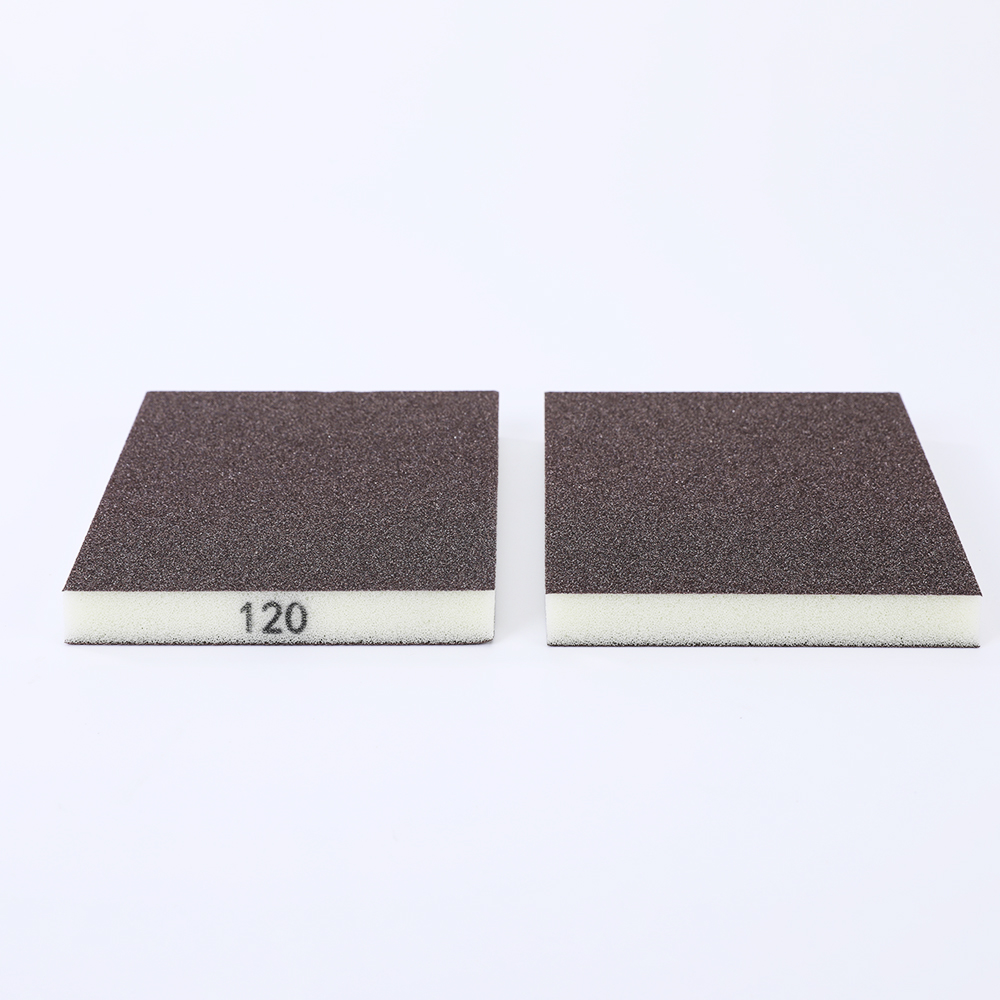

Sponge sandpaper

15.5 INR/Piece

Product Details:

- Usage for surface preparation and finishing

- Product Type abrasive

- Color brown

- Material High-density sponge, Brown alumina

- Click to View more

X

Sponge sandpaper Price And Quantity

- 13.00 - 20.00 INR/Piece

- 15.5 INR/Piece

- 1000 Piece

Sponge sandpaper Product Specifications

- High-density sponge, Brown alumina

- abrasive

- for surface preparation and finishing

- brown

Sponge sandpaper Trade Information

- Shanghai

- Paypal Cash Advance (CA) Cash in Advance (CID) Telegraphic Transfer (T/T) Western Union Letter of Credit (L/C)

- 300000 Piece Per Month

- 2 Week

- Free samples are available

- 25 kg per sack/ drum, 1 ton per bag/ pallet

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO9001: 2015, ISO14001

Product Description

I. Product Definition and Composition

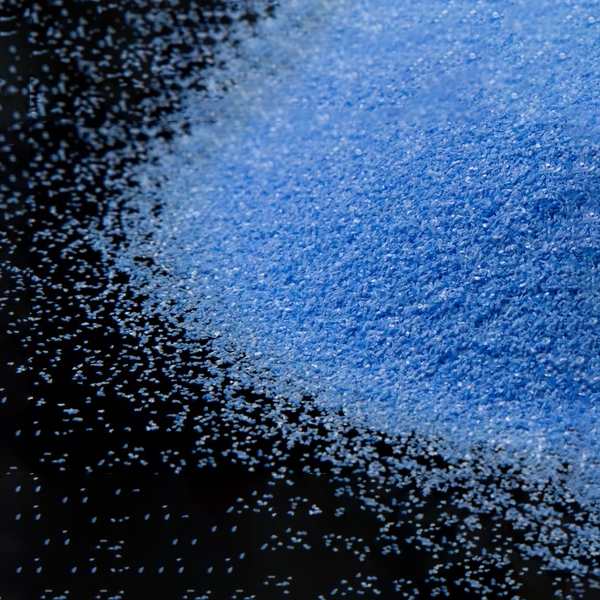

Core Composition: Made with flexible sponge as the base material, embedded with abrasive particles such as diamond sand and aluminum oxide, and compounded through adhesive bonding and flocking processes.

Alias System: Also known as sponge sanding blocks, polishing blocks, resin grinding blocks, and plastic grinding blocks, depending on the shape and application.

II. Manufacturing Process

Base Material Processing: The sponge is cut and shaped to ensure uniform porosity.

Abrasive Compounding: Abrasive particles are fixed onto the sponge surface using adhesive bonding or electrostatic flocking technology.

Post-Processing: Custom shapes (square, round, irregular) are cut using molds, and some products undergo hydrophobic or corrosion-resistant coating treatments.

III. Core Performance Advantages

Flexibility:High elasticity sponge base conforms to curved surfaces (e.g., automotive bodywork, carved furniture) for seamless grinding.

Versatility:Water-absorbent structure supports long-term wet grinding (reduces dust) and regains elasticity when dry, allowing for repeated washing and reuse.

Durability:Special treatment versions can withstand weak acids/alkaline cleaning agents and are suitable for corrosive environments like metal rust removal.

Customization:Available in multiple grit sizes (20-400 mesh), with dimensions from ranging hand-sized blocks to industrial rolls, suitable for both manual fine grinding and mechanical operations.

IV. Typical Applications

Home Manufacturing:

-

Precision grinding of curved surfaces on solid wood furniture and paint surface transition treatment.

-

Polishing of complex patterns on decorative crafts.

Industrial Manufacturing:

-

Smoothing of stainless steel welds (wet grinding to prevent overheating).

-

Removal of parting lines on injection-molded parts.

Automotive Repair:

-

Smoothing of interfaces in localized repainted areas.

-

Cleaning of wheel hub oxidation layers.

Special Materials Processing:

-

Beveling of acrylic/glass edges (wet grinding with coolant to prevent chipping).

-

Surface finishing of composite materials (carbon fiber).

V. Selection and Technical Considerations

Grit Matching:

-

Coarse grinding (80-120 mesh)

-

Fine grinding (150-240 mesh)

-

Superfine polishing (300 mesh+)

Base Material Hardness:

-

Soft (suitable for paint surfaces)

-

Hard (for metal rust removal)

Process Compatibility:

-

When using with power tools, select the reinforced adhesive type to prevent detachment at high speeds.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Abrasive Media' category

Send Inquiry

Send Inquiry