Call us now

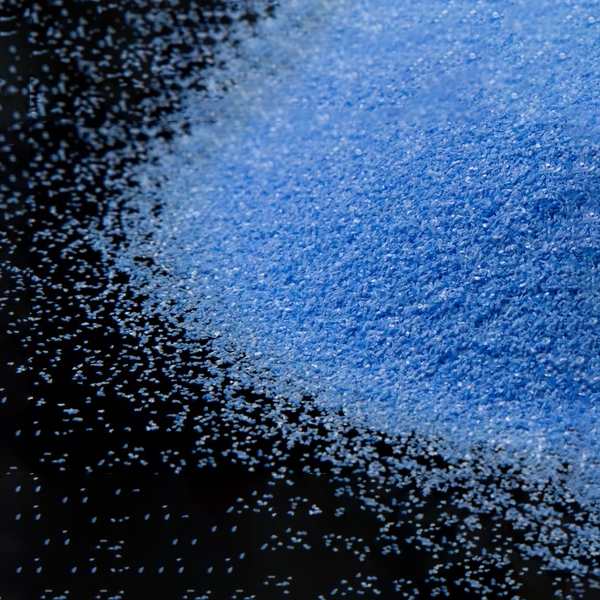

ZA25 Zirconia Alumina Blasting Media

Product Details:

ZA25 Zirconia Alumina Blasting Media Price And Quantity

- 100 Kilograms

- 120.0 INR/Kilograms

ZA25 Zirconia Alumina Blasting Media Trade Information

- Shanghai

- 300000 Kilograms Per Month

- 2 Week

- Yes

- ' r s s r ' Free samples are available

- 25 kg per bag/ drum, 1 ton per bag/ pallet

- ' l l ' All India

- ISO9001: 2015, ISO14001

Product Description

Features

Resistant to thermal shock.

Excellent toughness and self-sharpening ability.

Sandblasting performance remains consistent.

High strength even under heavy loads.

Small crystal size and longer service life.

Low consumption rate, more economical in the long run.

No iron contamination, protecting the surface integrity of the workpiece.

Replace fused alumina, silicon carbide.

Suitable for centrifugal disc finishers, wheel blast machines, vibratory finishing machines, and air-blasting cabinets.

Suitable for surface pretreatment, surface polishing, and coating removal processes.

Applications

Suitable for surface treatment of marble and super-hard steel;

Remove thick contaminants such as rust, scale, and old coatings;

Manufacture high-grade refractory materials and wear-resistant products;

Used to produce hot-pressed steel wheels with heavy loads;

Used to produce cutting discs, grinding discs, polishing wheels and other raw materials in the abrasive industry;

Used to produce heavy rough material grinding wheels in the mechanical processing industry, heavy-duty industrial load grinding wheels, high-grade resin bonded grinding wheels in the precision instrument manufacturing industry, rail grinding wheels in the railway industry, etc.

Grind and cut tough materials;

Cleaning hard surfaces and creating rough surface profiles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Abrasive Media' category

Send Inquiry

Send Inquiry